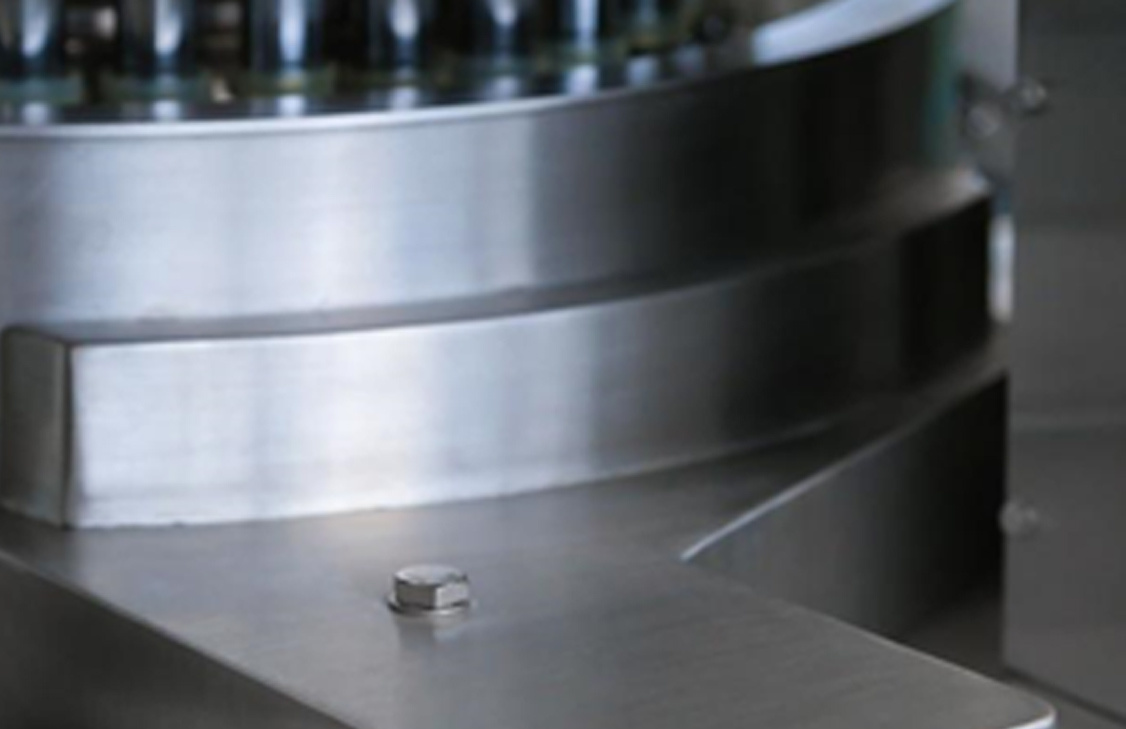

The tablet chamber adopts a closed structure, preventing external dust from entering, and has a dust collection device to prevent the die and guide rails from being contaminated by dust.

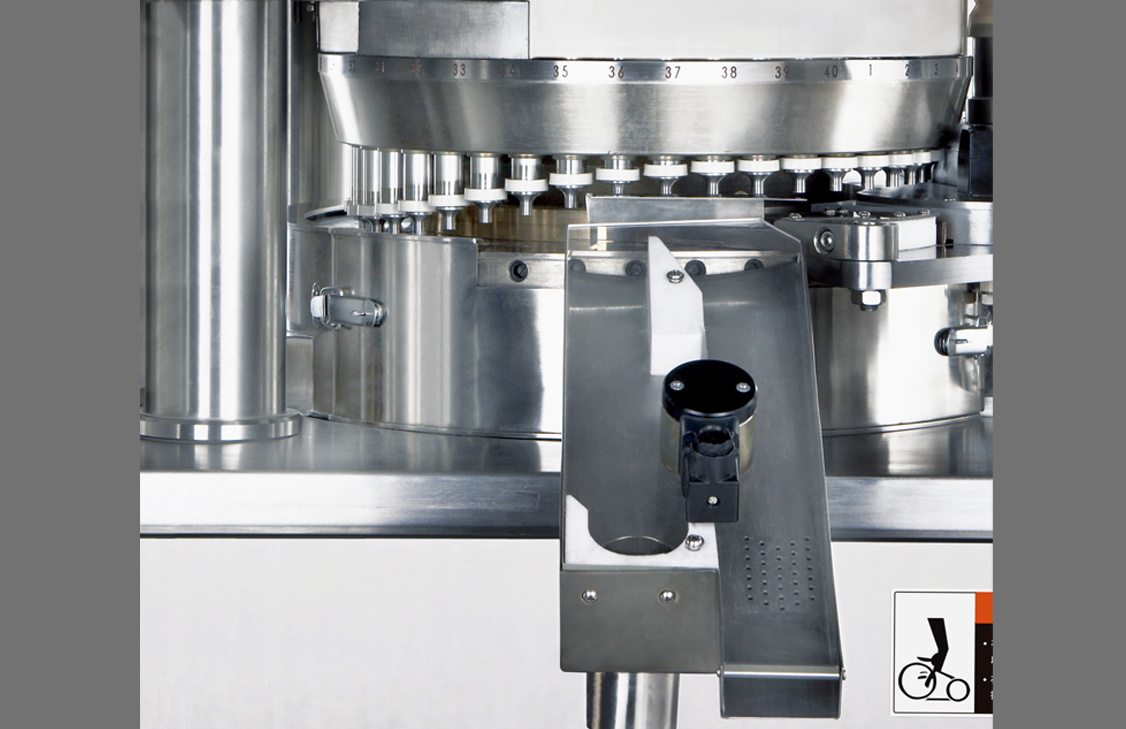

GZPT SERIES OF HIGH-SPEED ROTARY TABLET PRESS MACHINE

Retail price:

Market price:

编号:

重量:

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: GZPT SERIES OF HIGH-SPEED ROTARY TABLET PRESS MACHINE

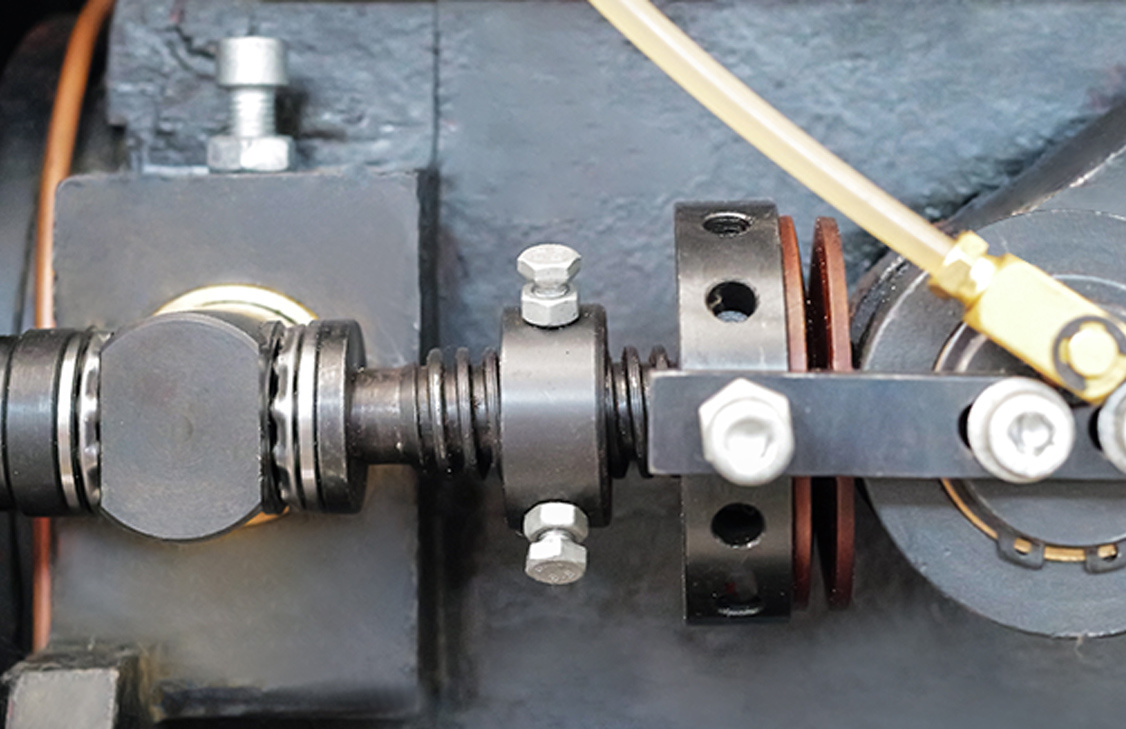

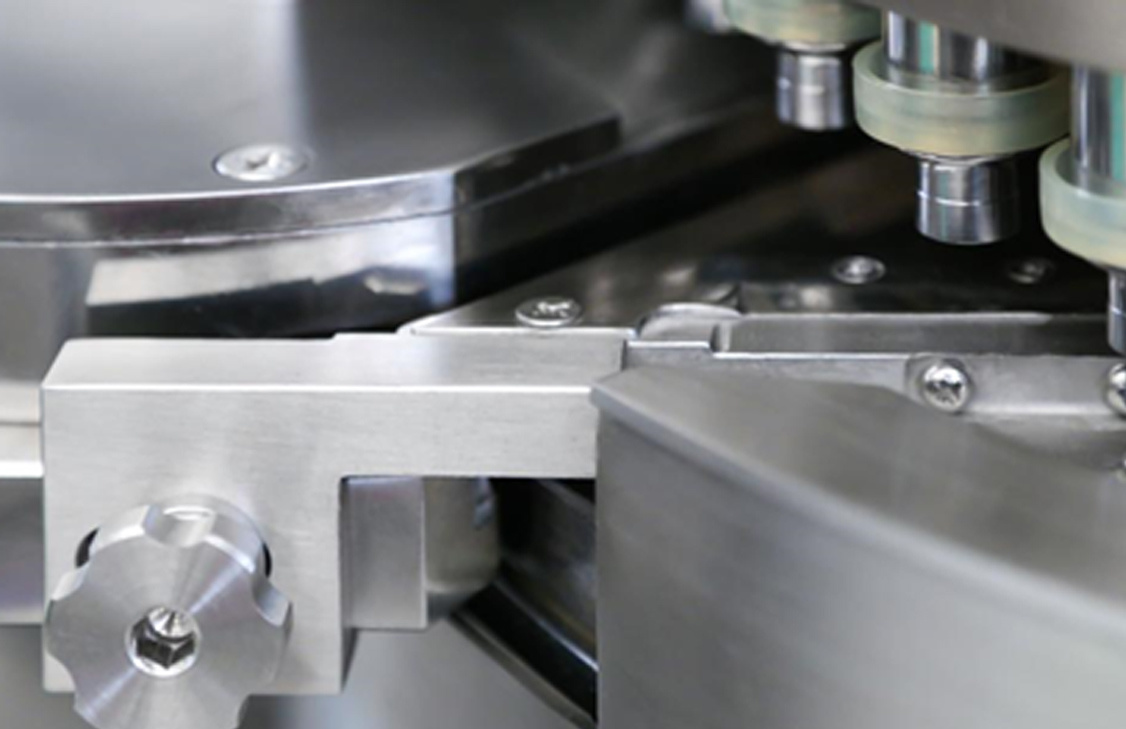

This machine adopt advanced PLC and big color touch screen, checking punch&die .pressure through imported pressure sensor, to achieve on-line checking and analyse and jndgement, Automoticlly adjust powder filling depth, to achieve automatical control during tablet production period meantime moroitoring punches&die situation and powder supply as safeguard which greatly reduce production cost, increase tablet qualitified rate high efficient.

Model GZPT-26 GZPT-32 GZPT-40 GZPT-45 Punch&die type(EU) D B BB BBS Number of press station 26 32 40 45 Max tablet diameter(mm) 25 16 13 11 Max abnormal prelate axis size(mm) 25 18 16 13 Max output (Tablet/h) 170000 210000 260000 280000 Max filling depth(mm) 20 18 18 18 Max main pressure(KN) 100 100 100 100 Max pre pressure(KN) 20 20 20 20 Idle load noise dB(A) <75 Power 380V 50HZ 12KW Size L×W×H(mm) 830×870×1995 Weight(kg) 1650 ※Double-layer tablet 、 ring tablet function or IPC control (for your choice)

Re: No additional information noted if there are any changes caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!