It is easy to change and adjust the mould.

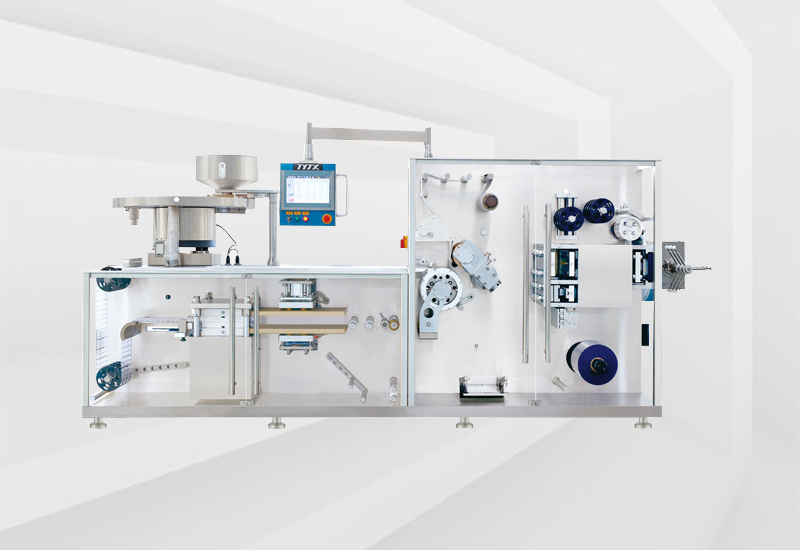

DPH-280 ROLLER BOARD BLISTER PACKAGING MACHINE MACHINE

Retail price:

Market price:

编号:

重量:

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: DPH-280 ROLLER BOARD BLISTER PACKAGING MACHINE MACHINE

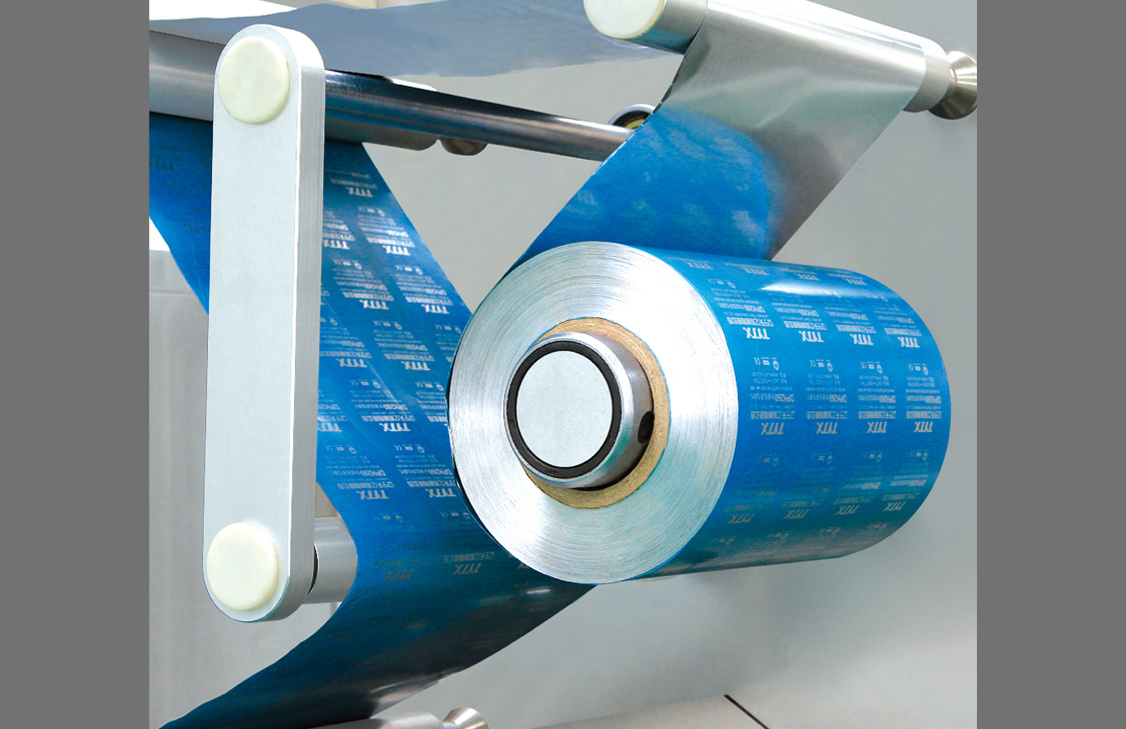

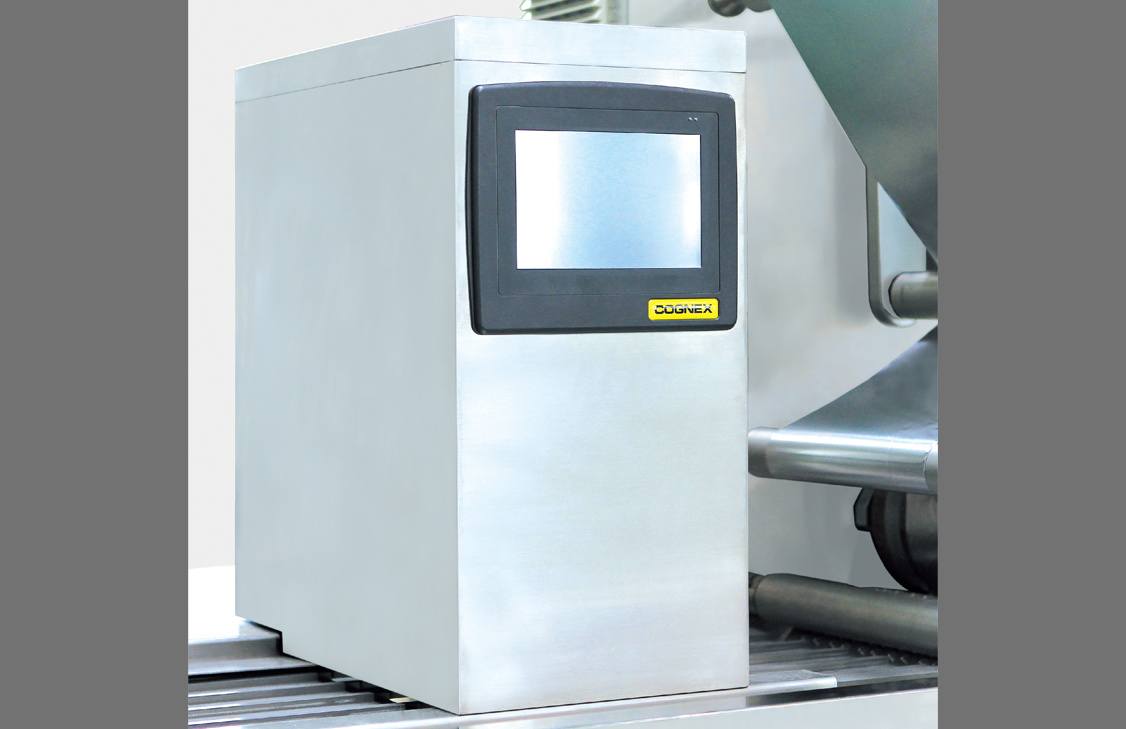

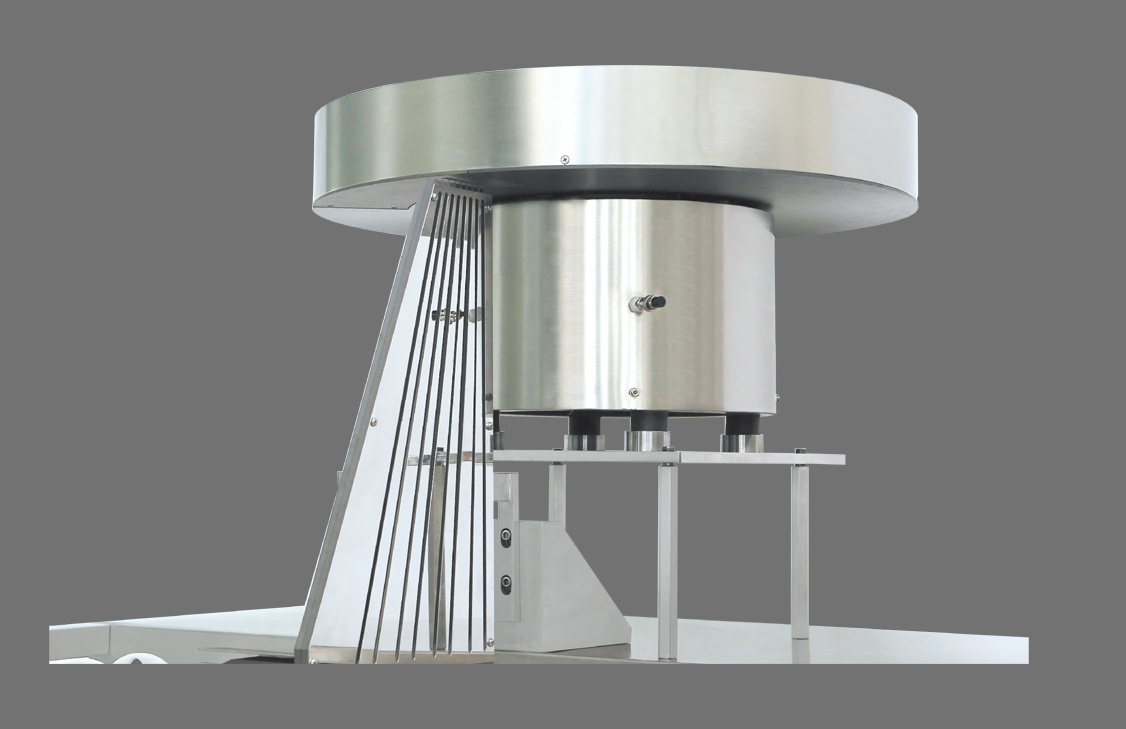

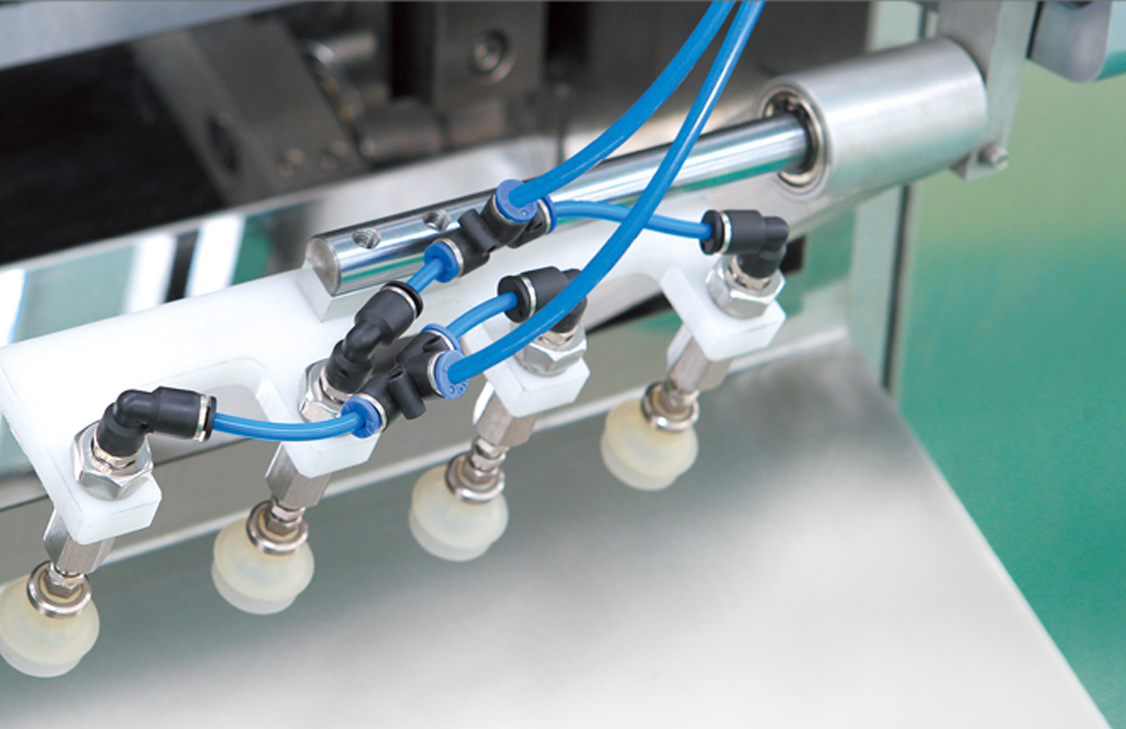

This machine adopt plate-type、positive pressure blow forming the blister, roller sealing with servo control system, insure the sealing and cutting can be transmited exactly. Also make it easy to operate、adjust、maintain and change the mould.</br> <strong>Performance Advantage</strong></br> 1.Six sets of independent servo motors used one the machine, make the machine run smoothly. Also it will make it easy to change and adjust the mould.</br> 2.All work process like PVC heating 、PVC forming 、Printing、Printing batch number、cutting and so on, can be controled by HMI.</br> 3.Large molding area, the size and shape of the plate can be arranged reasonable.</br> 4.Vision system and rejection system can be choosed. With this the disqualification product will be rejected. The function of laser registration and servo control insure the plate transmited and cutted more accurate.

Model DPH-280 Max output 480 blisters/min Max Cutting Frequency 120 cuts/min Max Forming Area(mm) 240×260 Max Forming Depth 10 Max Steping Distance 240 Packaging Material(mm) PVC\PP\PVDC 260×(0.25~0.35) Aluminum Foil 260×(0.02~0.025) Air Consumption (L/min) 450 Water Consumption (L/min) 3.2 Power 380V 50HZ 20KW Size L×W×H(mm) 3200×1100×2100 Net weight(kg) 3000 Re:No additional information noted if there are any changed caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!