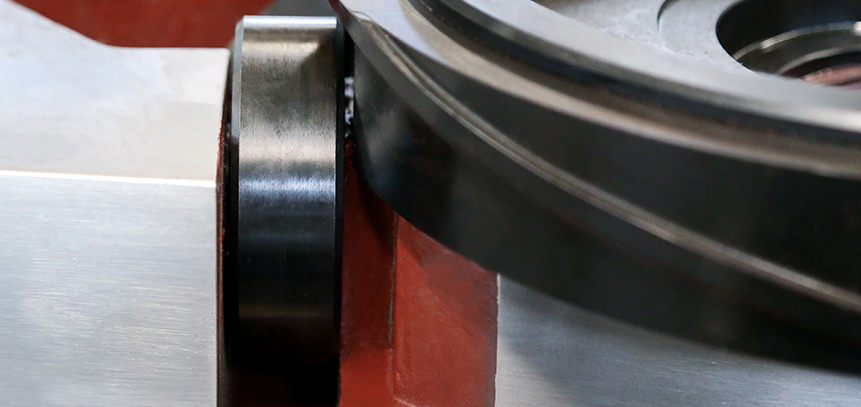

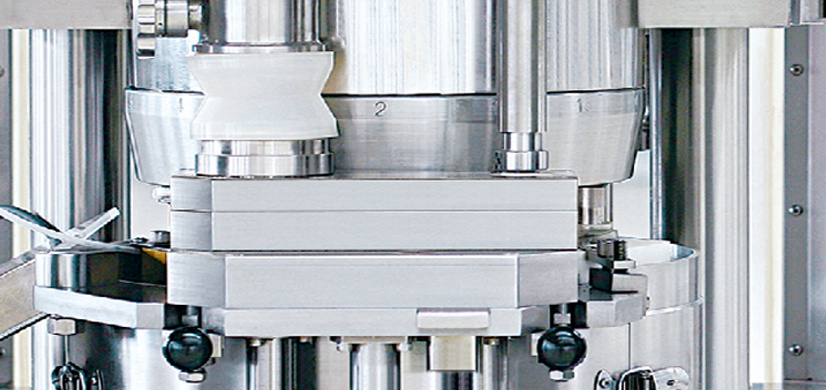

Large Diameter Design of Main Pressure Wheel

The large main pressure wheel extends the tablet compression time, making it more suitable for high-speed production of large-diameter traditional Chinese medicine tablets.

ZPT SERIES OF ROTARY TABLET PRESS MACHINE

Retail price:

Market price:

编号:

重量:

Quantity

-

+

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: ZPT SERIES OF ROTARY TABLET PRESS MACHINE

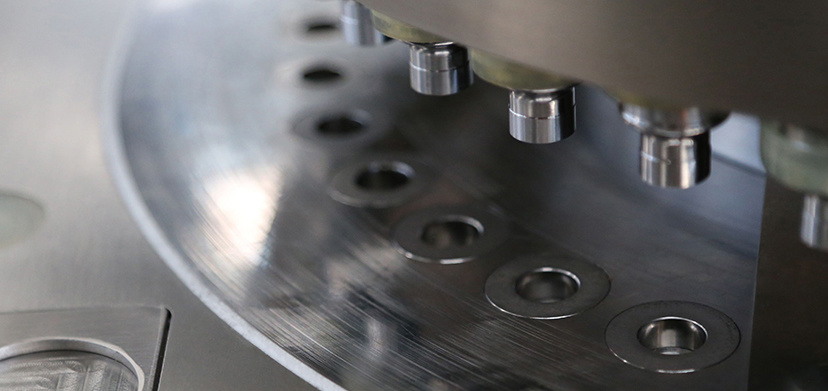

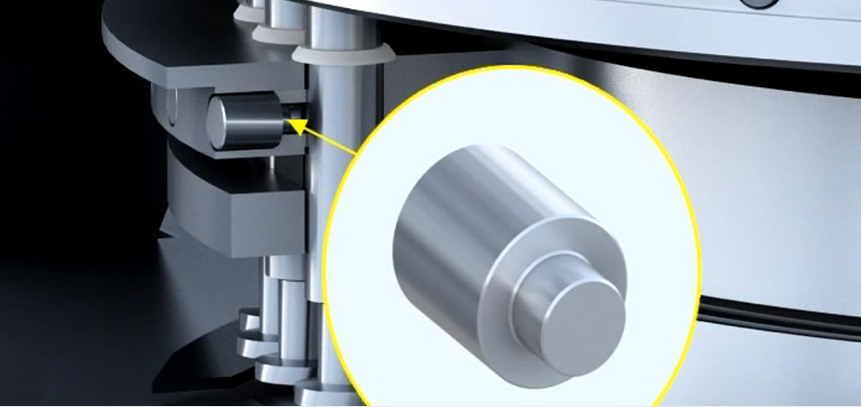

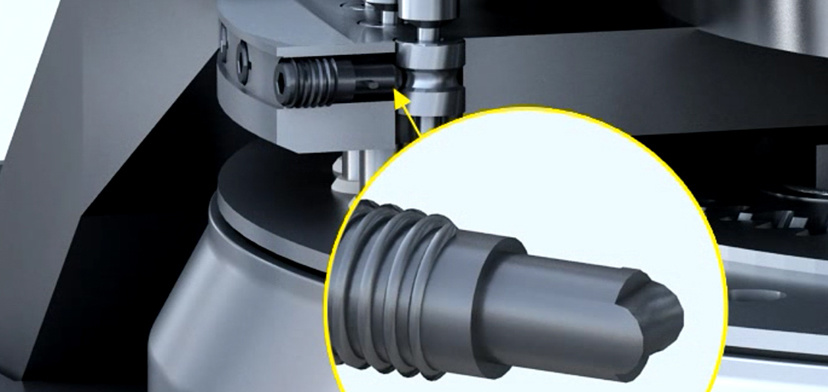

The contact with product adopt stainless stell. The hole of the punches & die is with special anti-leakage and anti-dust device. Convenient for disassemble structure ,make sure the maintenance. Adopt high definition,isolated window design. Adopt reliable safe sealing and dustproof design.

Model ZPT-15 ZPT-17 ZPT-20 ZPT-25 Punch&die type(EU) D B BB BBS Number of press station 15 17 20 25 Max tablet diameter(mm) 25 16 13 11 Max abnormal prelate axis size(mm) 25 18 16 —— Max output (Tablet/h) 70000 80000 95000 118000 Max filling depth(mm) 20 16 16 16 Max main pressure(KN) 100 80 80 80 Max pre pressure(KN) 12 12 12 12 Idle load noise dB(A) <75 Power 380V 50HZ 8.0KW Size L×W×H(mm) 640×675×1620 Weight(kg) 675 Re: No additional information noted if there are any changes caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!