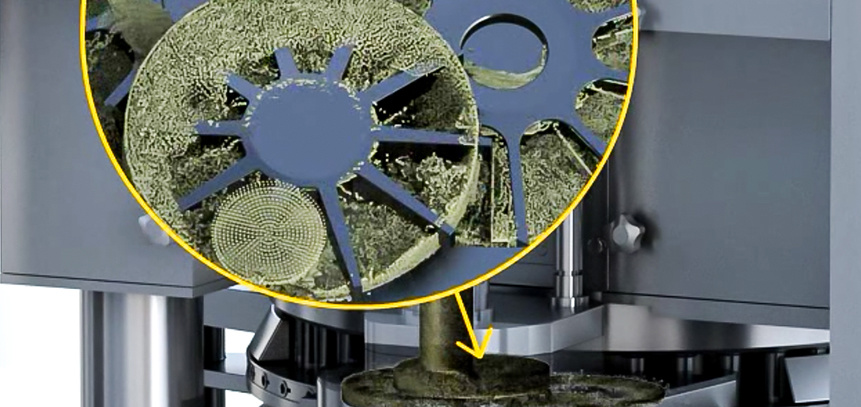

Uses a high-precision filling adjustment mechanism

Adopts a precision screw rod linkage inclined plane lifting mechanism, with quantitative guides along the inclined plane without gaps or return strokes. This ensures more precise quantification and high tablet weight control accuracy.

GZPTS-I SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

Retail price:

Market price:

编号:

重量:

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: GZPTS-I SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

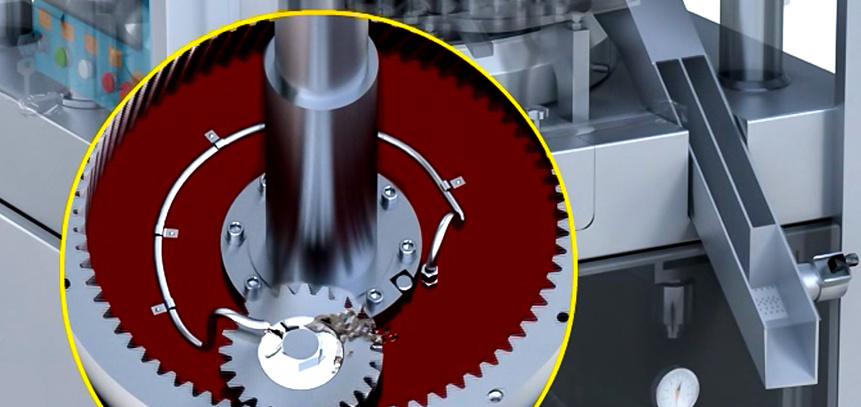

This series of machine can meet user requirements for different tablet size. It with high precision, advanced automation level, fast production speed, large output, stable and reliable performance, low noise and so on. This machine is absolutely compliance with GMP requirements. It’s an ideal equipment for pharmaceutical manufacturers to improve techniques and develop new projects.</br> <strong>Performance Advantage</strong></br> 1. Adopt two transmission mode, make the plate combination rotating around a fixed axis,ensure the stability of the plate combination when rotating at high speed.</br> 2.The main roller diameter is longer, ensure the pressure time, more suitable for large diameter and traditional Chinese medicine tablets production.</br> 3.Adopt the design of double block powder, powder leakage quantity is less.</br>

Model GZPTS-I 55 GZPTS-I 65 GZPTS-I 85 Punch&die type (EU) D B BB Number of press station 55 65 85 Max tablet diameter(mm) 25 16 13 Max abnormal prolate axis size(mm) 25 18 16 Production range(Tablet/h) 52800-528000 62400-624000 81600-816000 Max filling depth(mm) 20 18 18 Max main pressure(KN) 100 100 100 Max pre pressure(KN) 20 20 20 Idle load noise dB (A) <85 Power 380v 50HZ 18.5KW Size L x W x H(mm) 1355×1525×1950 Weight (kg) 4250 ※ Optional: Double-layer tablet or ring tablet function(for your choice)

Re: No additional information noted if there are any changes caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!