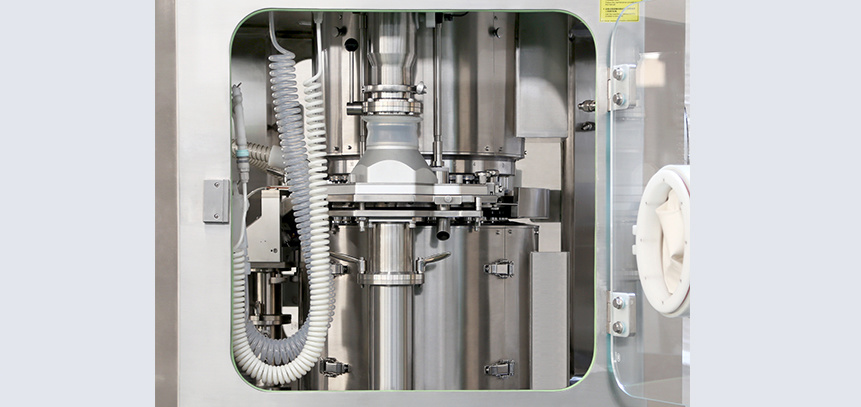

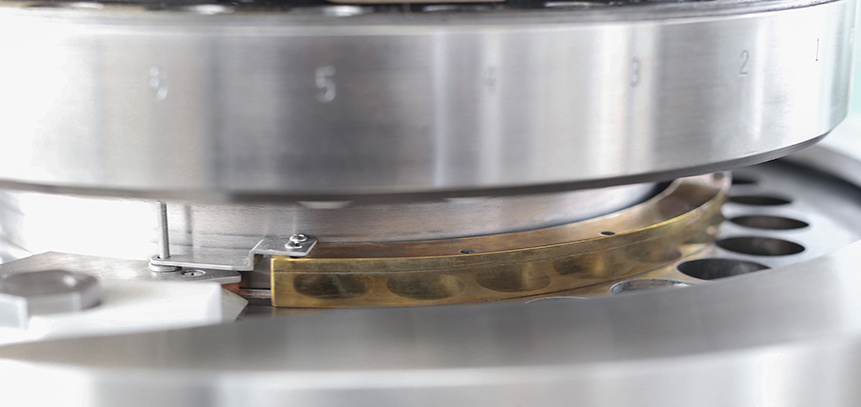

Closed-type tablet compression chamber structure

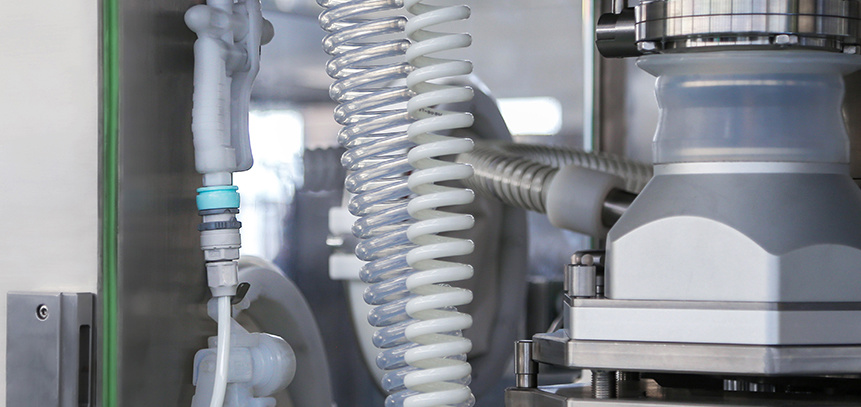

Closed-type tablet compression chamber structure, made entirely of 304 stainless steel. The chamber's tempered glass door uses an inflatable airbag seal, maintaining a slight negative pressure of around -50pa during production. It features automatic locking and detection functions.

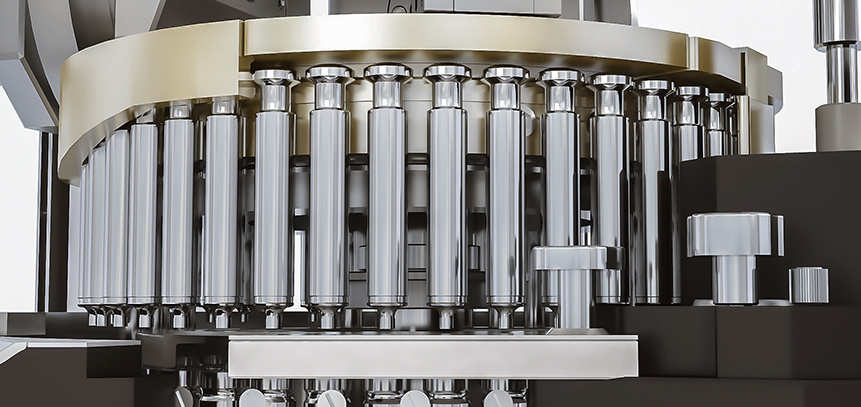

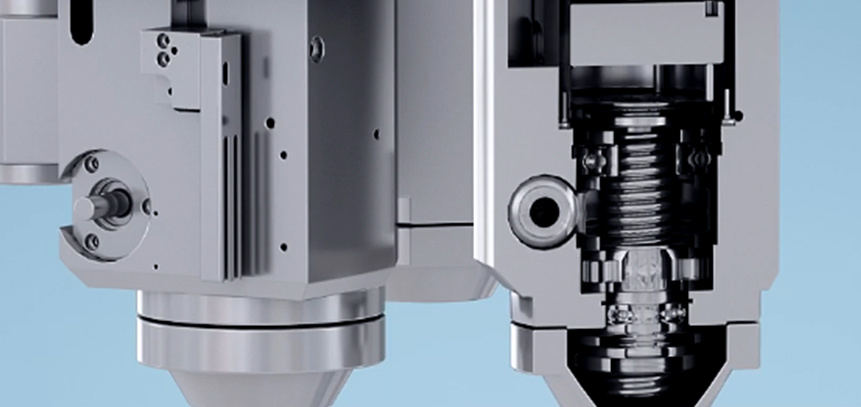

GZPT-Y(OEB) SERIES OF HIGH-SPEED ROTARY TABLET PRESS MACHINE

Retail price:

Market price:

编号:

重量:

Quantity

-

+

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: GZPT-Y(OEB) SERIES OF HIGH-SPEED ROTARY TABLET PRESS MACHINE

The closed die-compressing chamber is made of 304 stainless steel. The tempered glass door of the die-compressing chamber is sealed with an inflatable airbag, maintaining a slight negative pressure of about -50pa during production, and has automatic locking and detection functions.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!