Features a dual-layer tablet compression function.

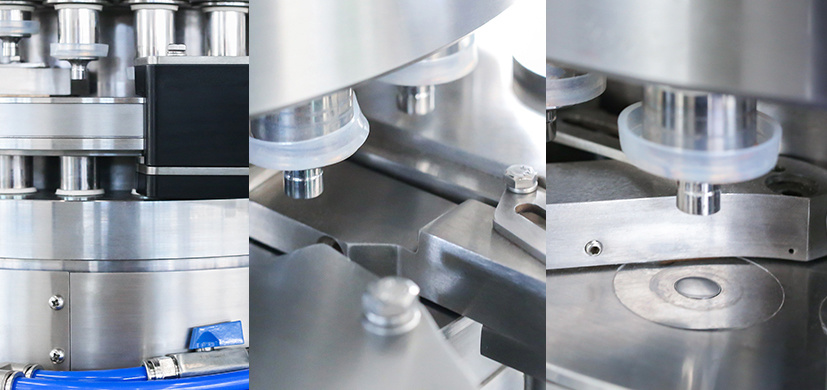

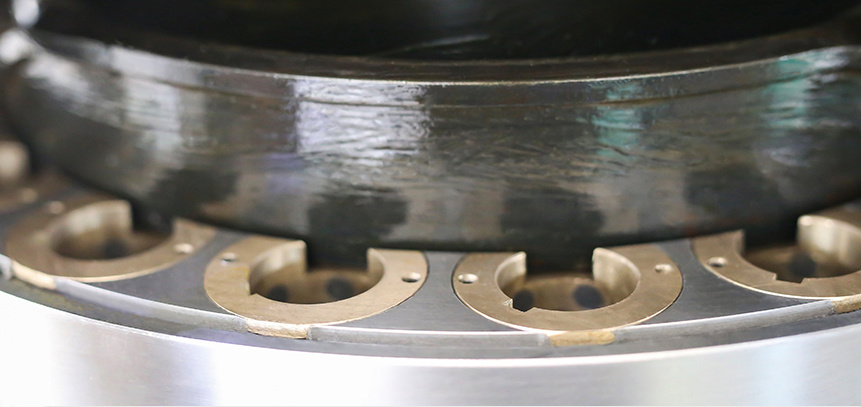

This machine features a structural design with dual-side feeding and dual-side pressing, enabling the compression of double-layer tablets.

ZPTS Series Rotary Tablet Press

Retail price:

Market price:

编号:

重量:

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: ZPTS Series Rotary Tablet Press

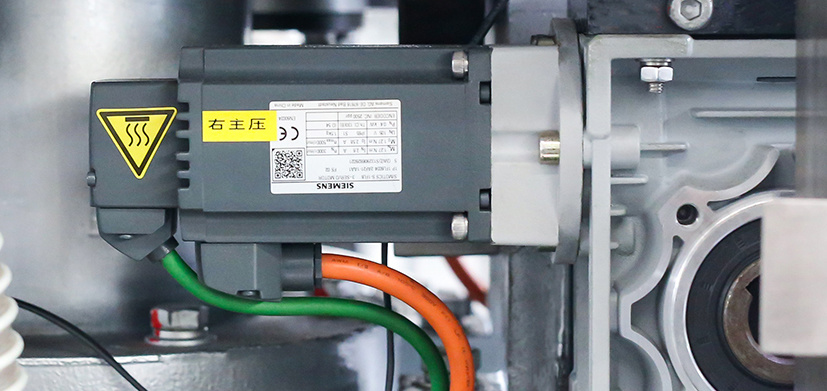

This machine is a small, rotary-type tablet press with dual-discharge outlets. The main motor features stepless speed regulation via a Siemens frequency converter, delivering high torque and allowing for continuously adjustable production speeds. Employing an accurate pressure detection and acquisition system coupled with optimized computational processing, the system automatically adjusts tablet weights by standardizing parameter settings for different pharmaceutical products, ensuring stable tablet weight variation. It also features multiple protective functions.

Model ZPTS-19 ZPTS-23 Punching die number 19 23 Punch type D B Maximum yield per single layer (tablets/h) 68,400 82,800 Maximum yield of double-layer tablets (tablets/h) 34,200 41,400 Maximum tablet diameter (mm) Φ25 Φ16 Maximum non-circular long-axis dimension (mm) 25 18 Maximum filling depth (mm) 20 16

Maximum sheet thickness (mm) 8 Maximum principal compressive stress (kN) 80 Power requirements 380V 50HZ 7.5KW Maximum Overall Dimensions (mm) in Operating State (L×W×H) 680×680×1695 Net weight of the equipment (kg) 980

No-load maximum noise [dB(A)] ≤80

Note: We reserve the right to modify parameters without prior notice in case of any technical improvements.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!