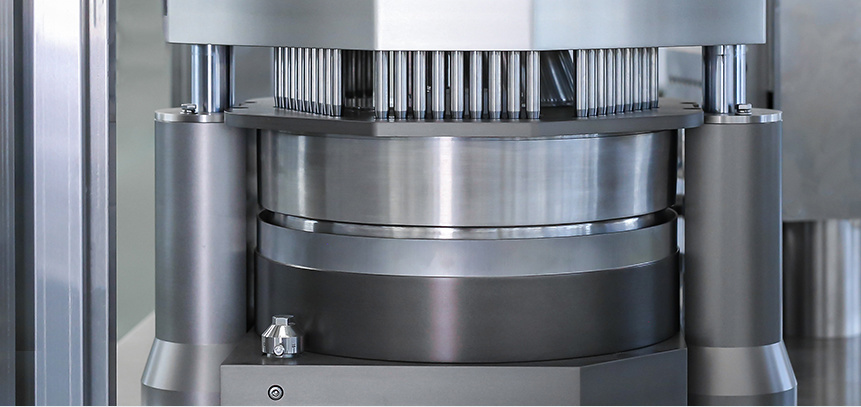

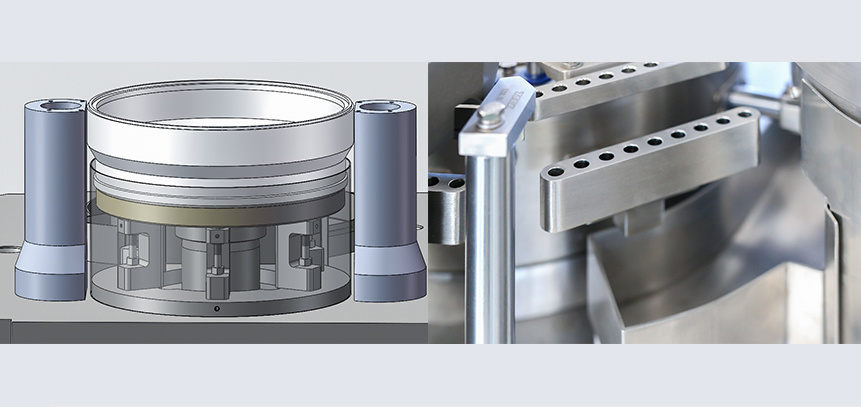

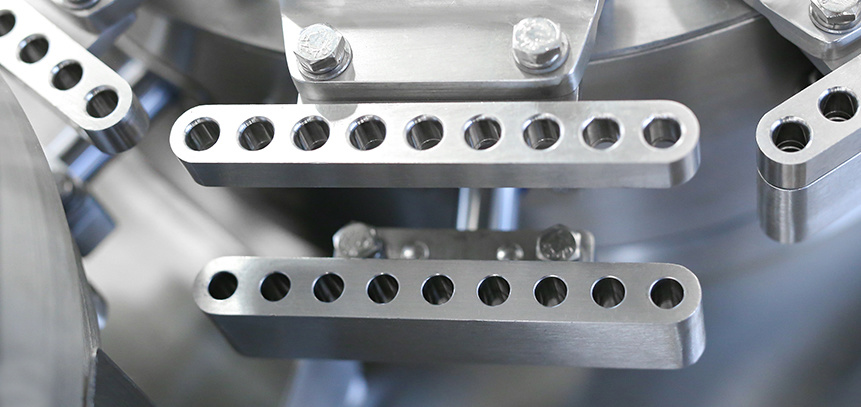

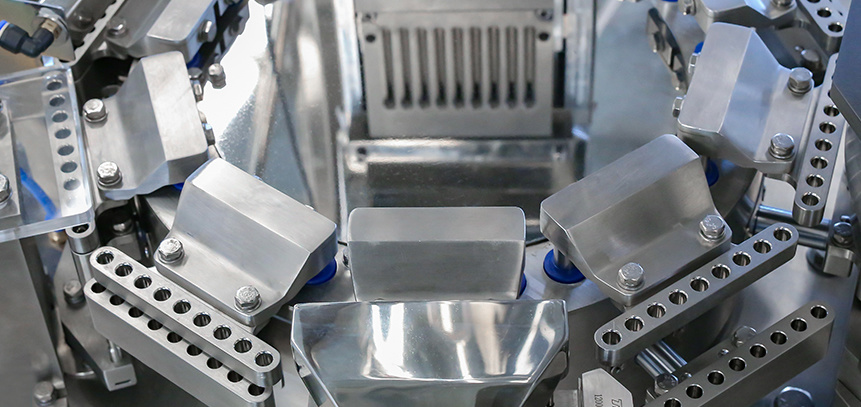

New vacuum capsule dispensing mechanism

New vacuum capsule dispensing structure, silicone material vacuum suction column, moderate softness and elasticity, can completely absorb the lower module holes, prevent vacuum leakage, and achieve better capsule dispensing effect.

NJP-1200 AUTOMATIC HARD CAPSULE FILLING MACHINE

Retail price:

Market price:

编号:

重量:

Quantity

-

+

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: NJP-1200 AUTOMATIC HARD CAPSULE FILLING MACHINE

PLC control and electronic components choose the international famous brand,such as Siemens、Schneider、Omron and so on,nice ,safely,reliablely. Touch screen and PLC control, scientifically, advanced, efficient. Advanced SEW motor and NASH vacuum pump guarantee the stability of the machine.

Model NJP-200 NJP-400 NJP-500 NJP-800 NJP-1200 No.of die orifice 2 3 4 6 9 Max output(capsule/hour) 12000 24000 30000 48000 72000 Vacuum -0.02 ~ -0.08 Mpa Capsule number 00#-5#; Safety type A, B (safety A,B) Filling percentage ≥99.9% Filling difference <±3 Idle load noise dB(A) <70 Power 380V 50HZ 5KW Size L×W×H(MM) 1156×941×1982 Weight (kg) 850 ※Data printing function,pellet device,dry vacuum pump or IPC control(for your choice).

Re:No additional information noted if there is any changed caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!