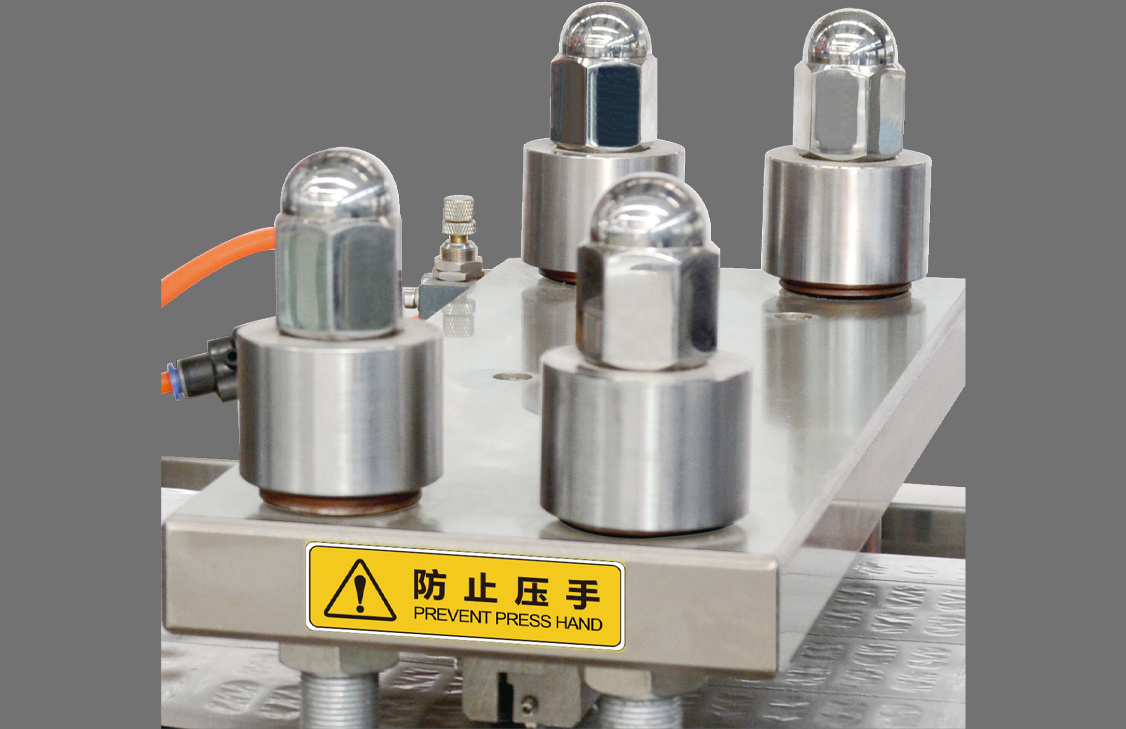

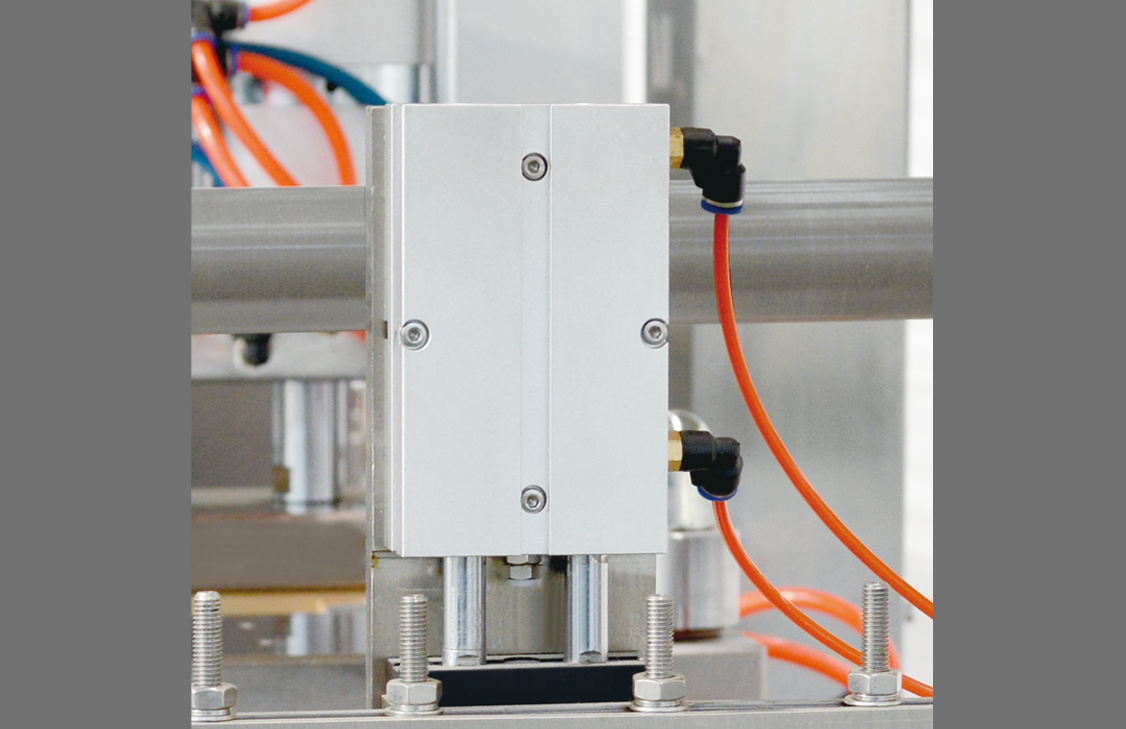

Sealing device adopts double pressurized cylinder , ensure the quality of platesealing .

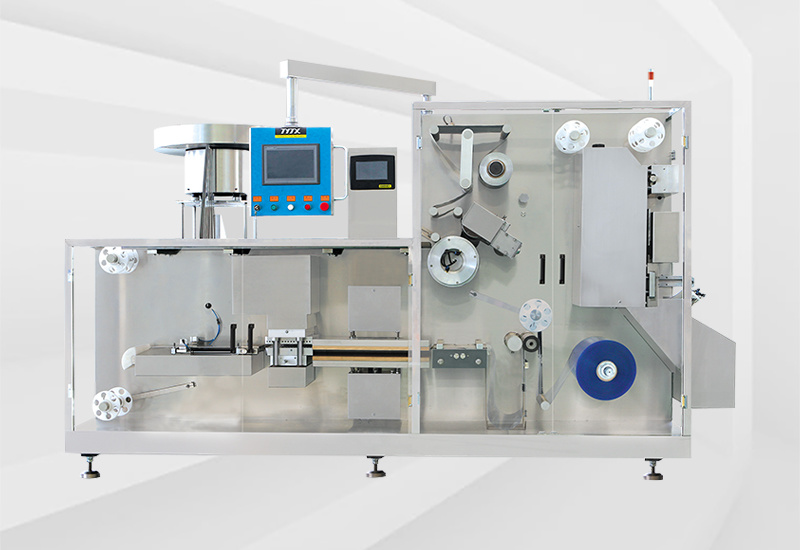

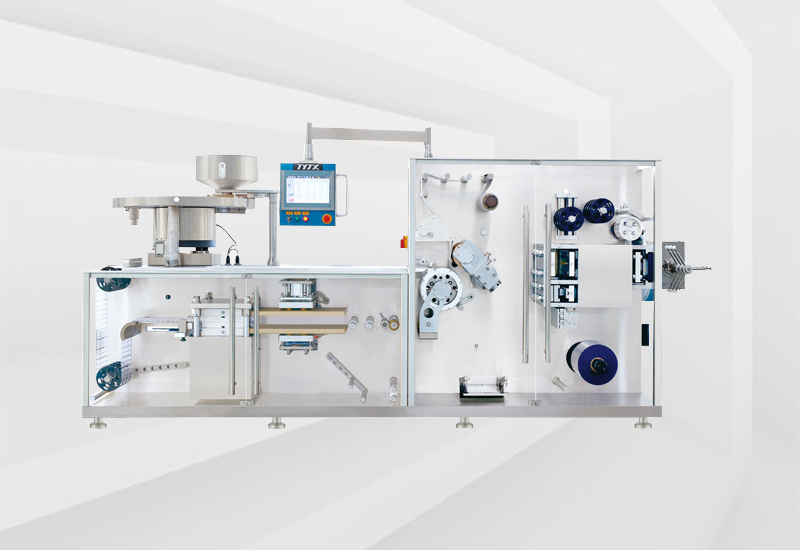

DPP-260 PLATE TYPE PACKAGING MACHINE

Retail price:

Market price:

编号:

重量:

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: DPP-260 PLATE TYPE PACKAGING MACHINE

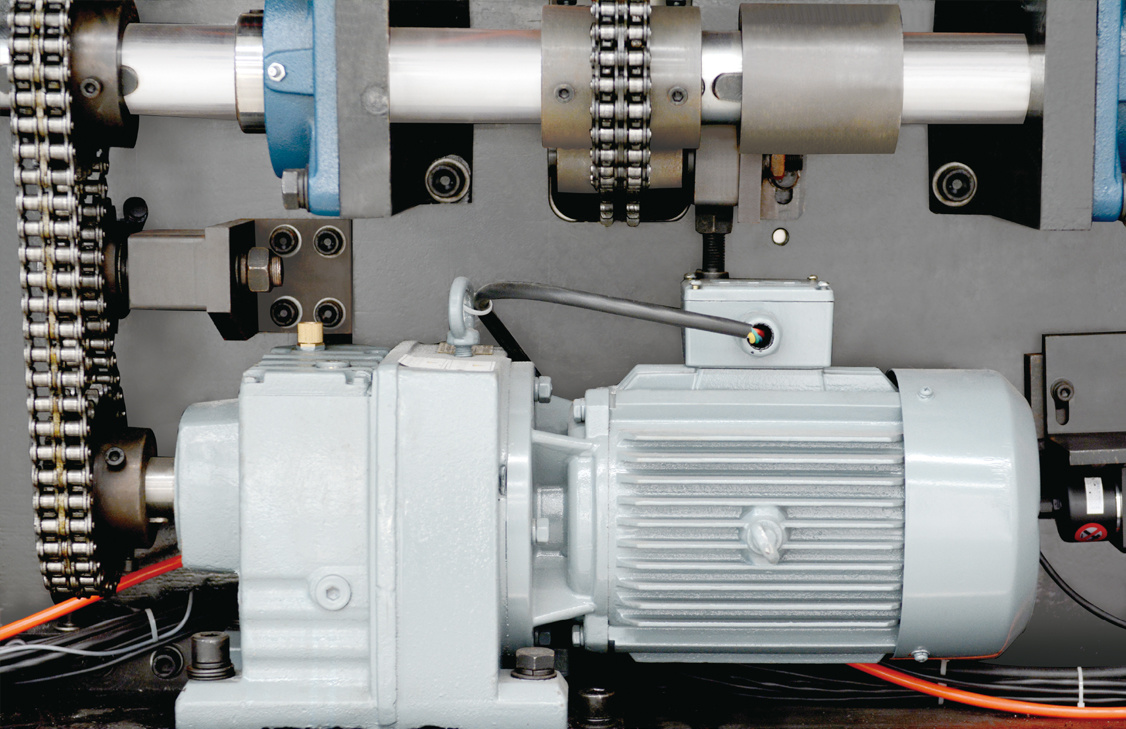

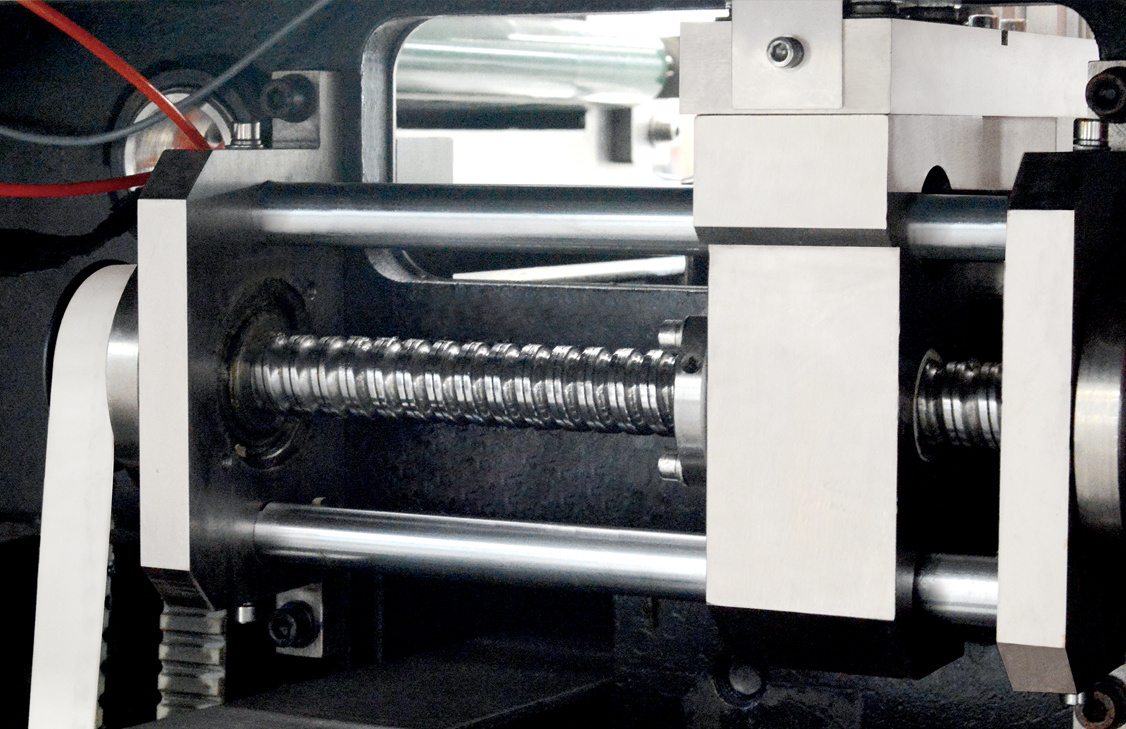

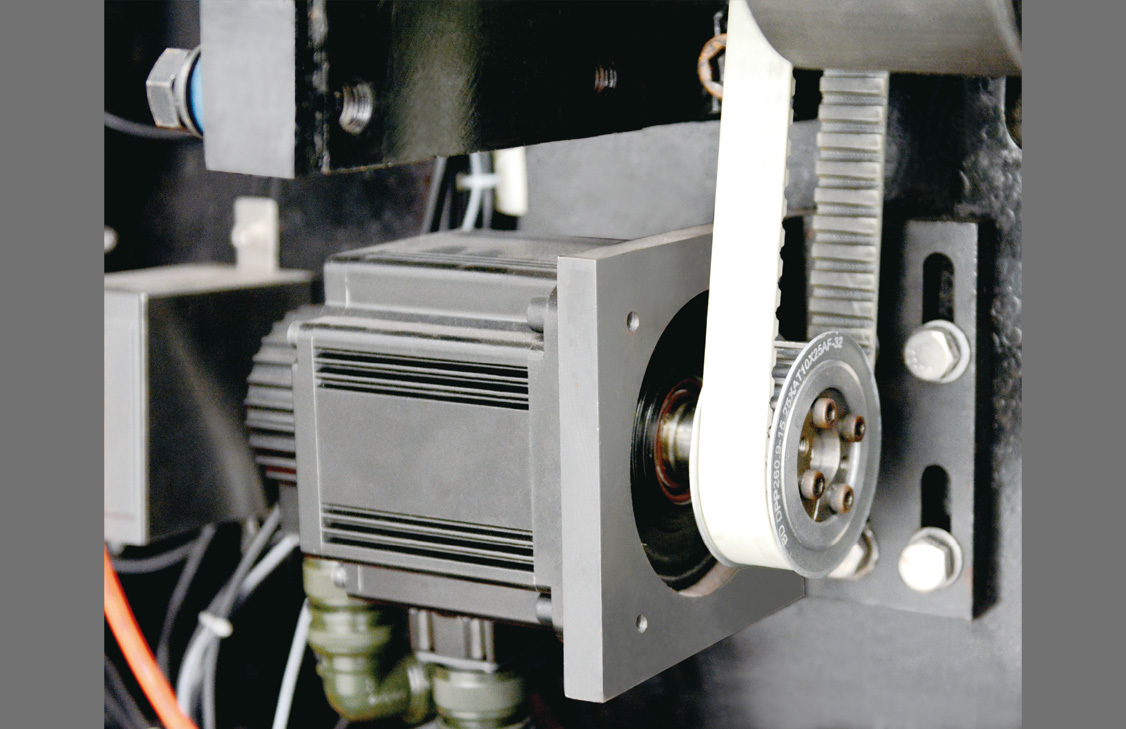

The machine has the reasonable design , novel structure.Equipped with automatic feeding system、packing testing、plate cooling integral、waste recycling and other devices, can automatically complete the package material feed, blister molding, drug filling, packing testing, heat sealing, batch number, indentation, blanking, scrap plate rejection, finished product output and other process. The production process is intuitive, easy operation and maintenance, complete functions.</br> <strong>Performance Advantage</strong></br> 1.Machine using PLC automatic control system, frequency control, high degree of automation. The main electrical components are used internationally renowned brands.</br> 2.The spline shaft of the forming mechanism, the sealing mechanism, the typewriting mechanism and the arbitration mechanism are all divided into three sections, single drive way, so as to improve the bearing capacity of the spline shaft, greatly improve the production efficiency and quality of the plate sealing, machines in operation process more smoothly and reduce the noise. Make the maintenance more convenient at the same time,reduce the working intensity and improve working efficiency.</br> 3. The forming mechanism, the sealing mechanism, the typewriting mechanism and the punching mechanism are all installed on the base of the guide rail, High positioning accuracy , move and adjust the position is convenient and accurate.

Model DPP-260 Max Cutting Frequency(cuts/min) 50 cuts/min Max Forming Area(mm) 160×250 Max Forming Depth 26 Packaging Material (mm) PVC/PVDC 260×(0.25~0.35) Air Consumption (L/min) 350 Water Consumption (L/min) 1 Power 380V 50HZ 12KW Size L×W×H(mm) 4280×860×1744 Weight (kg) 3500 Re:No additional information noted if there are any changed caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!