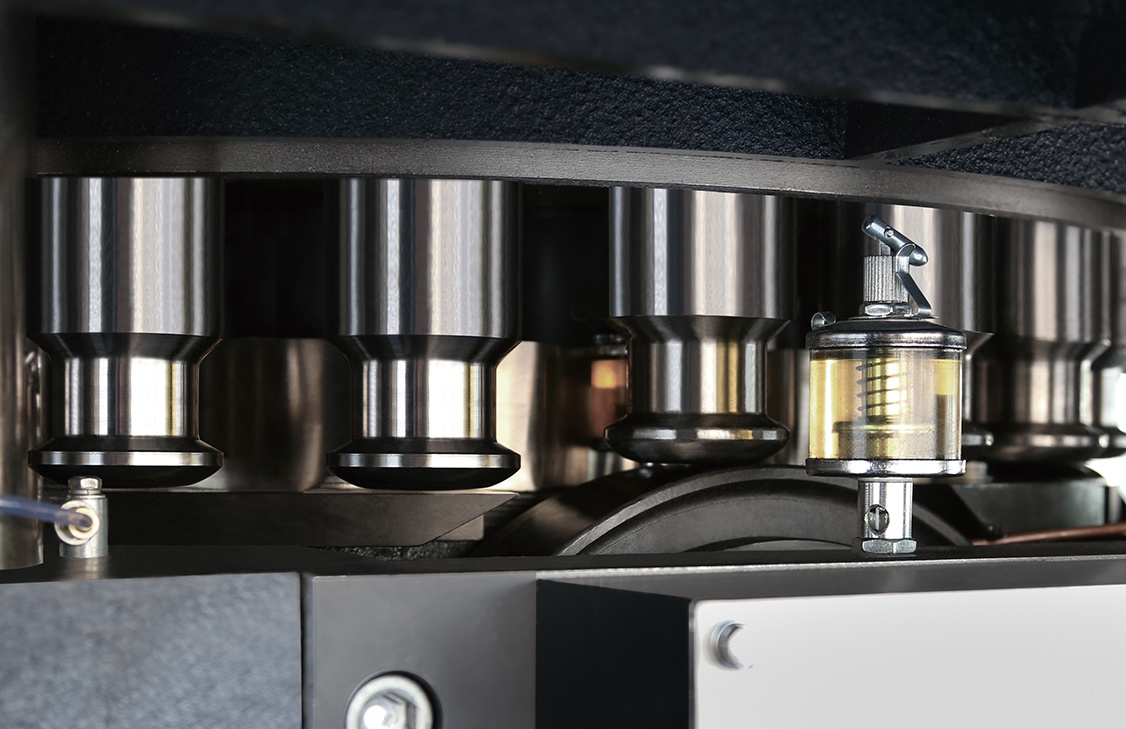

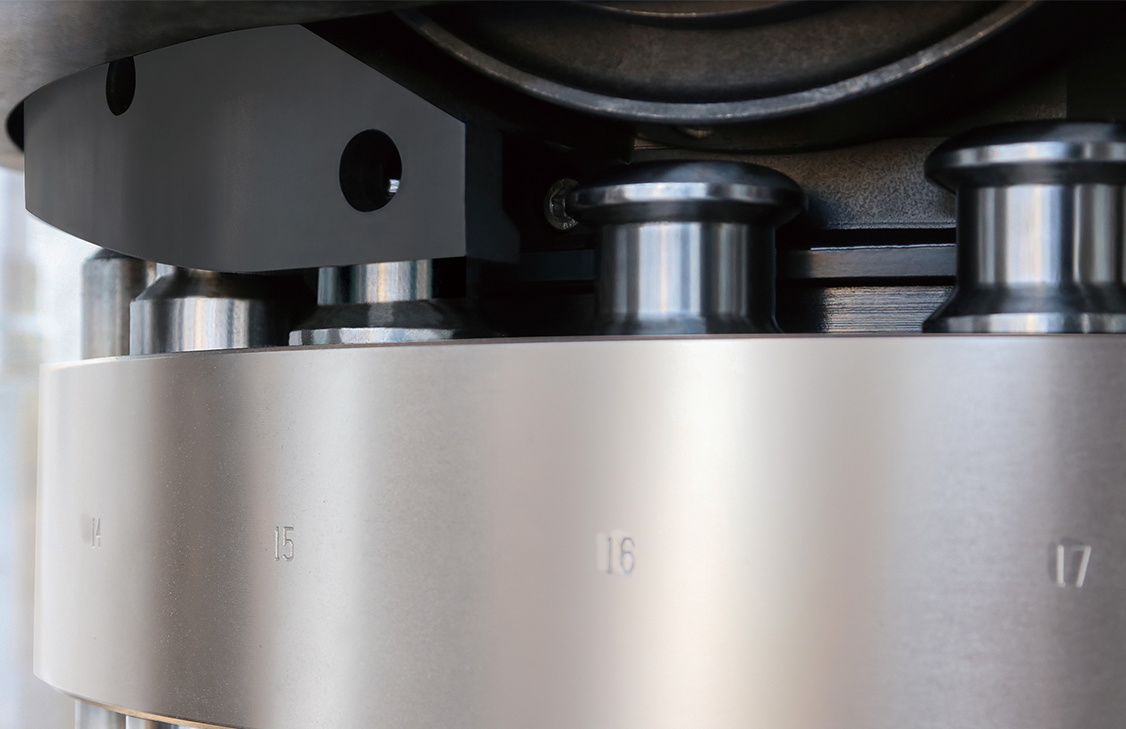

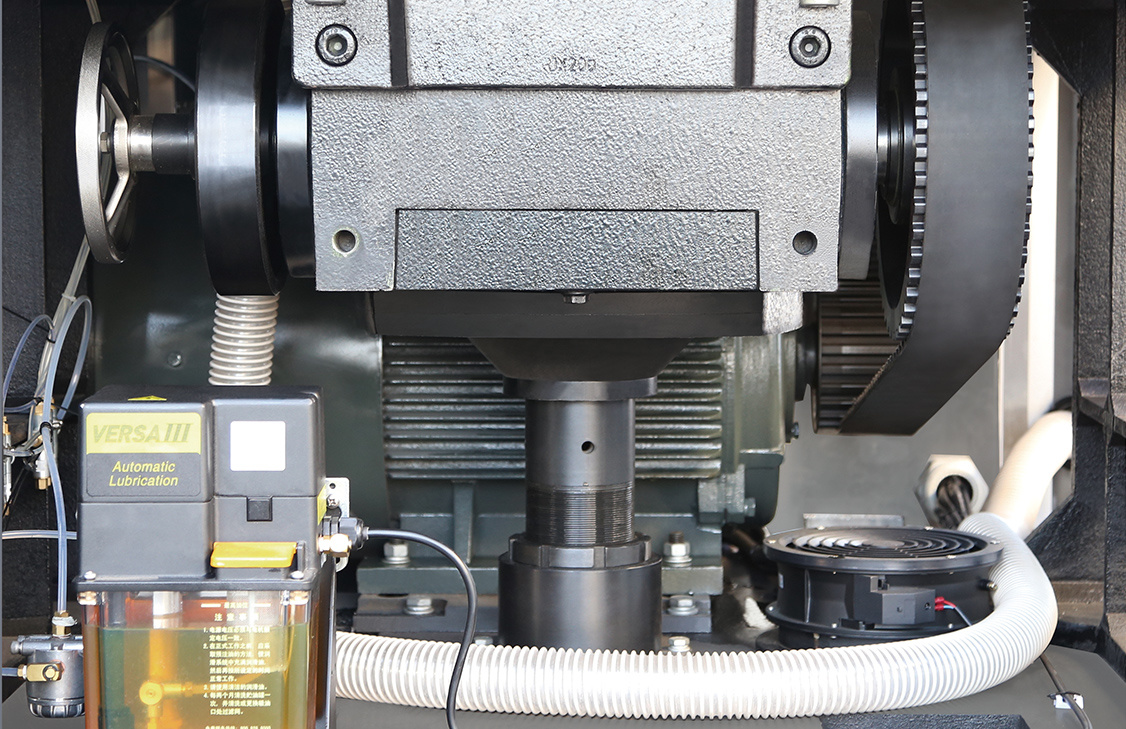

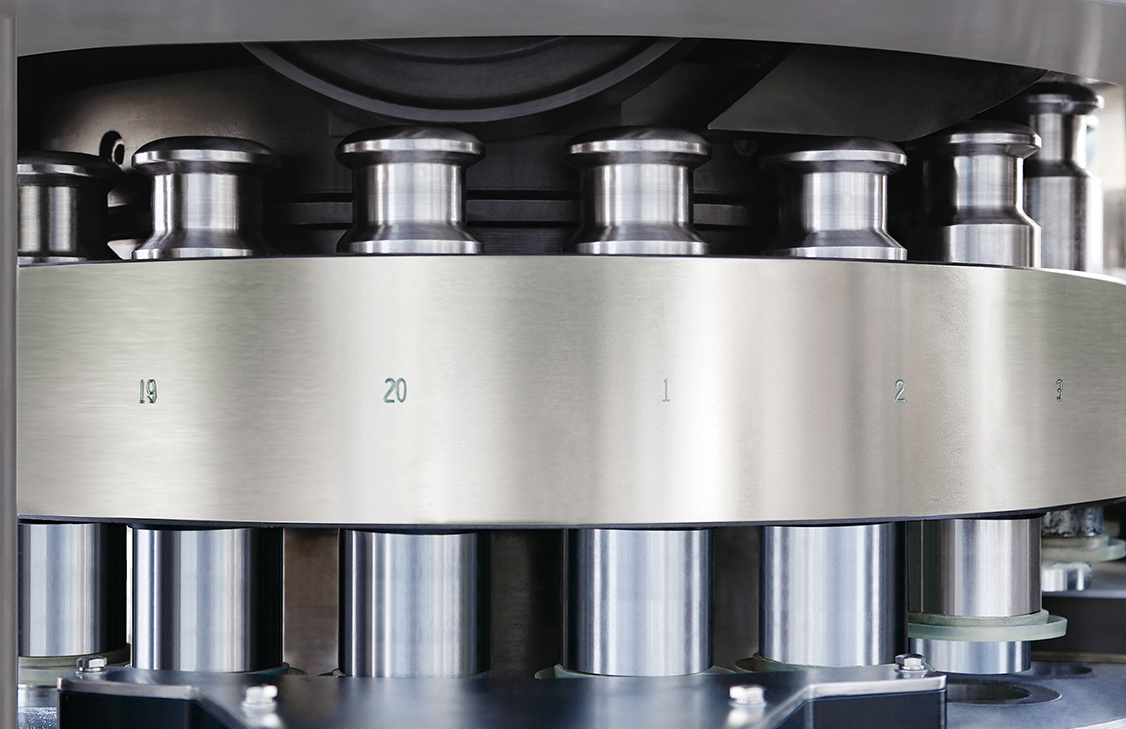

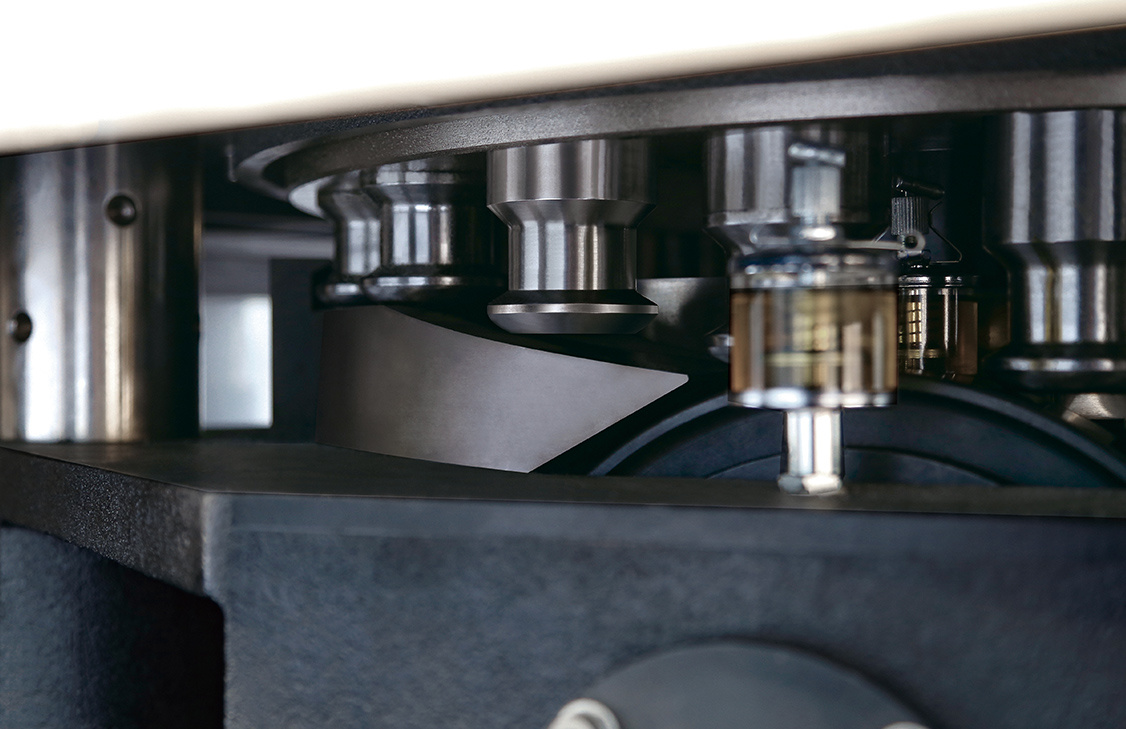

The main and pre-compression rollers have the same structure, realizing a modular design. Both the main and pre-compression rollers are made of special bearing steel with precision machining, and the sizes are the same, completely interchangeable, facilitating installation and reducing later costs.

ZPTZ SERIES HEAVY TABLET PRESS MACHINE

Retail price:

Market price:

编号:

重量:

Quantity

-

+

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: ZPTZ SERIES HEAVY TABLET PRESS MACHINE

This equipment is a new type of heavy duty tablet press, which can press large tablets, super thick tablets, stable operation and strong performance.Widely used in pharmaceutical, food chemical and other fields.

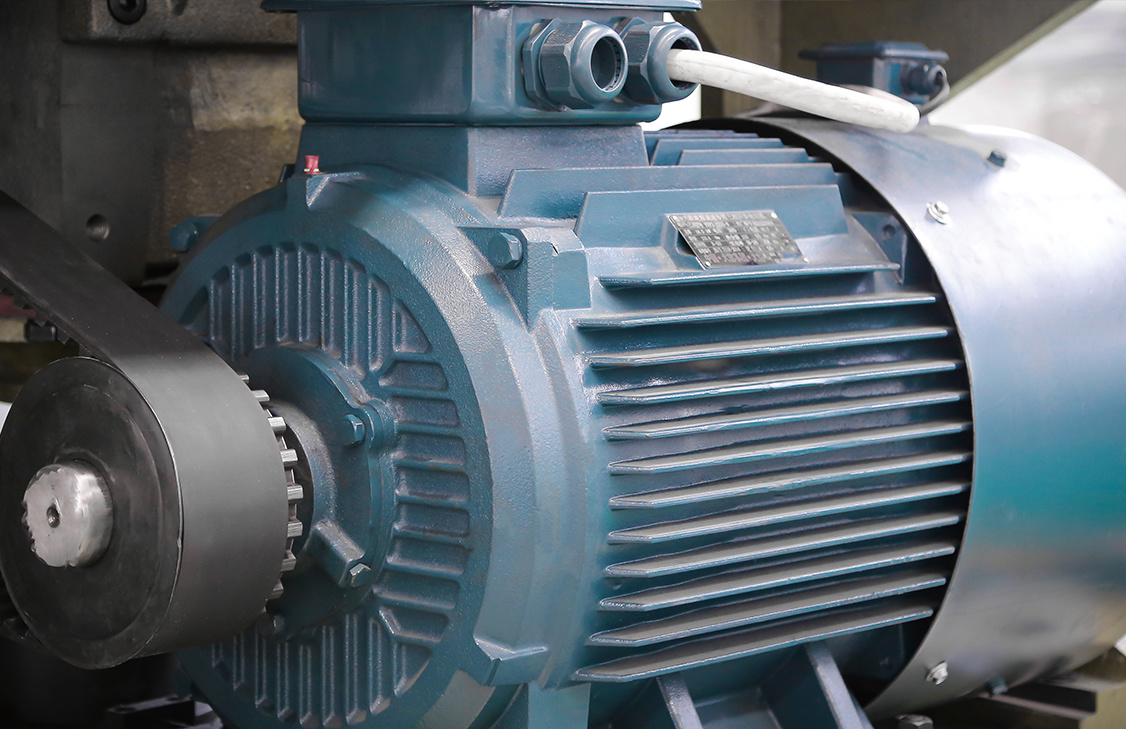

Model ZPTZ-20 ZPTZ-24 Punch&die type (EU) D B Number of press station 20 24 Max tablet diameter(mm) 60 50 Tablet thickness(mm) 25-35 10-20 Max filling depth(mm) 53 40 Max output(Tablet/h) 21000 25200 Max main pressure(KN) 400 Rotary speed(R/min) 5-17.5 Main motor power(Kw) 18.5 Power 380V 50Hz 25KW Size L x W x H(mm) 1400x1230x2186 Weight (kg) 5100 Re: No additional information noted if there are any changed caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!