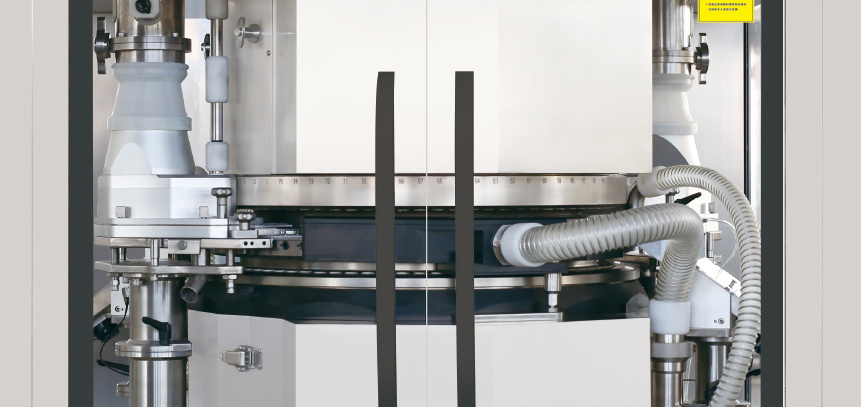

High-rigidity frame structure

The four columns, bottom plate, intermediate platform, and top plate form a rigid body. The stresses generated during the machine's operation under load cancel each other out, ensuring stable operation and low noise.

GZPTS700 SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

Retail price:

Market price:

编号:

重量:

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: GZPTS700 SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

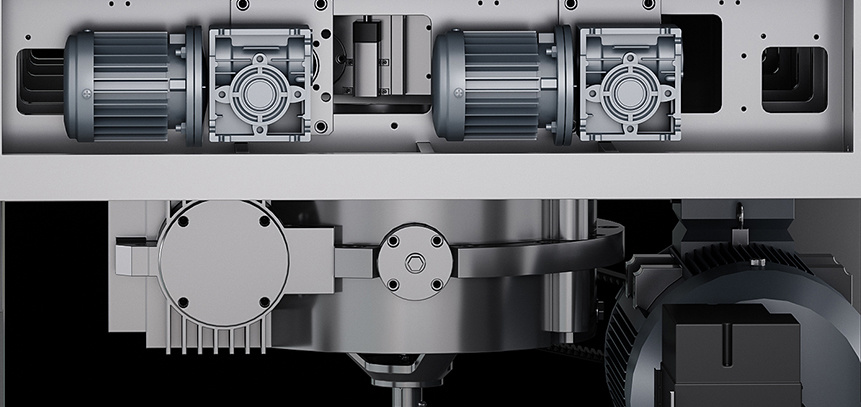

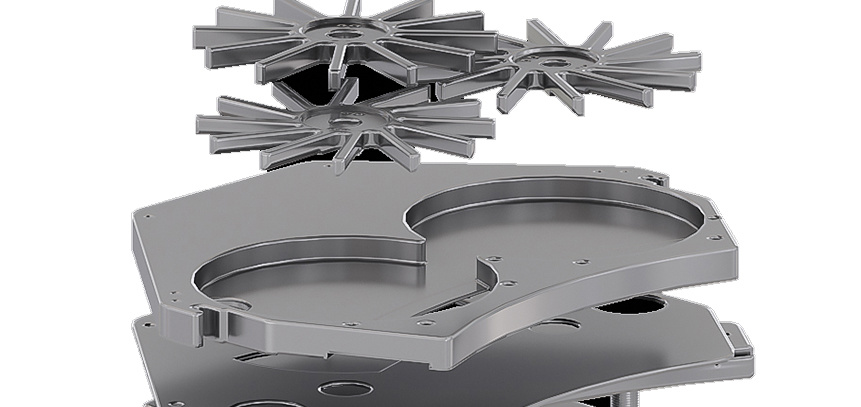

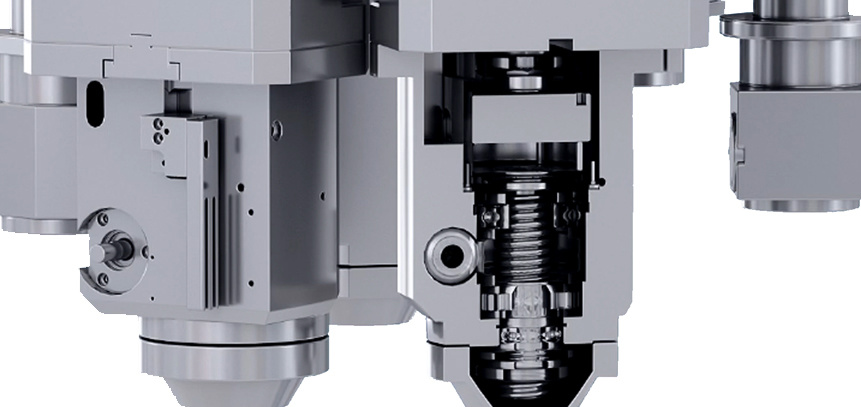

All-round innovation, large space, easy to clean, operate and maintain. </br> The GZPTS700 series double-discharge high-speed tablet press is characterized by high manufacturing precision, advanced automation level, fast production speed, stable and reliable operation, and low operating noise. </br> By combining innovative technology with intelligent control, the machine is more advanced, improving the quality of drug production, improving the production environment, reducing labor intensity, reducing raw material consumption, and lowering production costs. </br> It meets the audit and requirements of pharmaceutical regulatory authorities and is the ideal equipment for pharmaceutical factories to implement production technology transformation and new projects and meet GMP requirements.

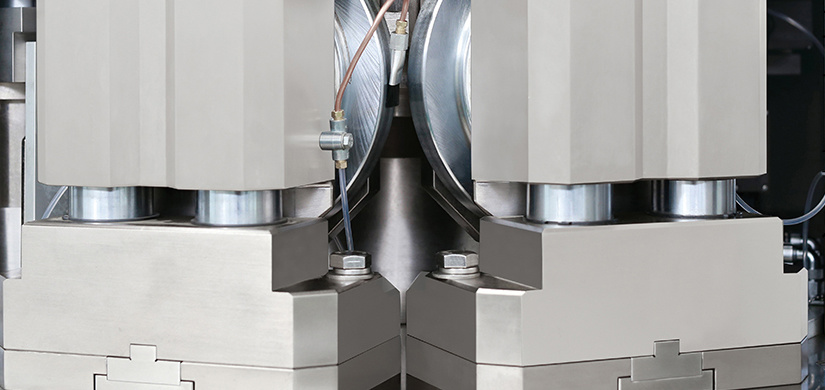

Model GZPTS700 51 63 75 81 Punch&die type(EU) D B BB BBS Number of press station 51 63 75 81 Max tablet diameter(mm) 25 16 13 11 Max abnormal prolate axis size(mm) 25 18 16 13 Production range(Tablet/h) 48900-489000 60400-604000 72000-720000 77700-777000 Speed cycle ( R/min ) 8~80 Max filling depth(mm) 18 Max main pressure(KN) 100 Max pre pressure(KN) 100 Idle load noise dB(A) ≤85 Power 380V 50HZ 30 KW Size L x W x H(mm) 1430×1430×2250 Weight ( kg ) 5800 ※ Double-layer tablet、 ring tablet function or IPC control (for your choice)

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!