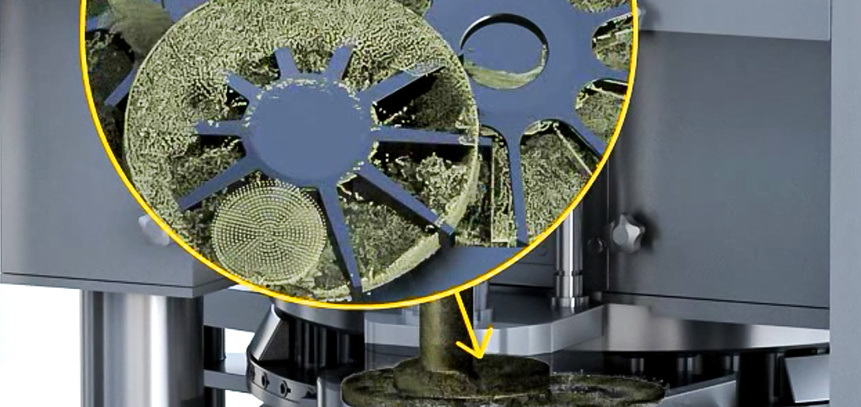

Uses a high-precision filling adjustment mechanism

Adopts a precision screw-driven inclined plane lifting mechanism. The quantitative guide rail is gapless along the inclined plane, with no return stroke lifting. This ensures more precise quantification and high tablet weight control accuracy.

GZPTS SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

Retail price:

Market price:

编号:

重量:

Remaining inventory

隐藏域元素占位

- Product Description

-

- Commodity name: GZPTS SERIES OF HIGH-SPEED DOUBLE-SLIDE TABLET PRESS MACHINE

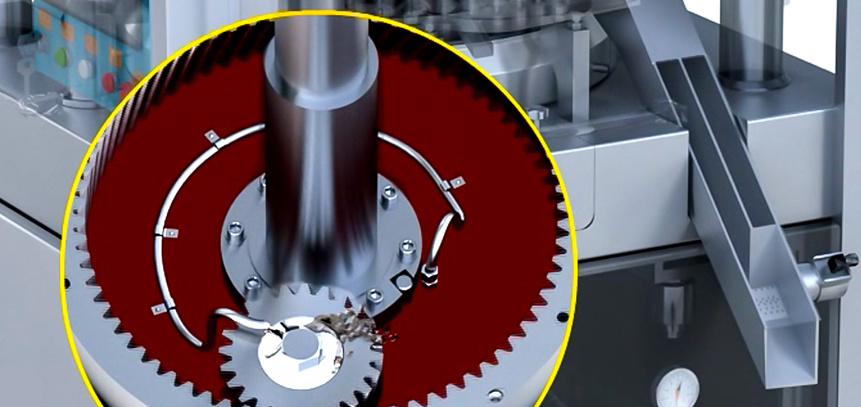

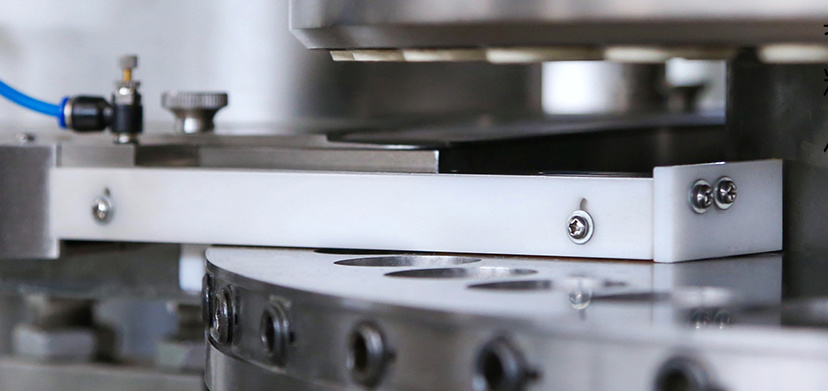

This series machine is with double-slide structure, It design reasonable, high production efficiency, high pressure, well stability, dust-proof facilities ,with double-layer tablet and ring tablet functions. It can widely used in pharmaceutical, chemical, food, electronics, metallurgy, daily necessities and other industries.</br> <strong>Performance Advantage</strong></br> Three sets of independent lubrication systerm.</br> 1. Thin oil lubrication system: thin oil filtering ,oil keep tidy all the time,effectively control temperature, which mainly act on main axis, pressure wheel ,inner ruler ring etc.</br> 2 .The electric grease lubrication system is used for lubricating hat of upper and lower punches&die,meanwhile with the decrease vibration and noise function.</br> 3 .Thin oil lubrication is used for lubricating upper and lower punches&die in the die plate.

Model GZPTS-45 GZPTS-55 GZPTS-75 Punch&die type (EU) D B BB Number of press station 45 55 75 Max tablet diameter(mm) 25 16 13 Max abnormal prolate axis size(mm) 25 18 16 Production range(Tablet/h) 43200-432000 52800-528000 72000-720000 Speed cycle (R/min) 8-80 Max filling depth(mm) 20 18 18 Max main pressure(KN) 100 100 100 Max pre pressure(KN) 20 20 20 Idle load noise dB( A) <85 Power 380V 50HZ 18.5KW Size L x W x H(mm) 1265×1485×1950 Weight (kg) 3750 ※Optional: Double-layer tablet or ring tablet function(for your choice)

Re: No additional information noted if there are any changes caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!