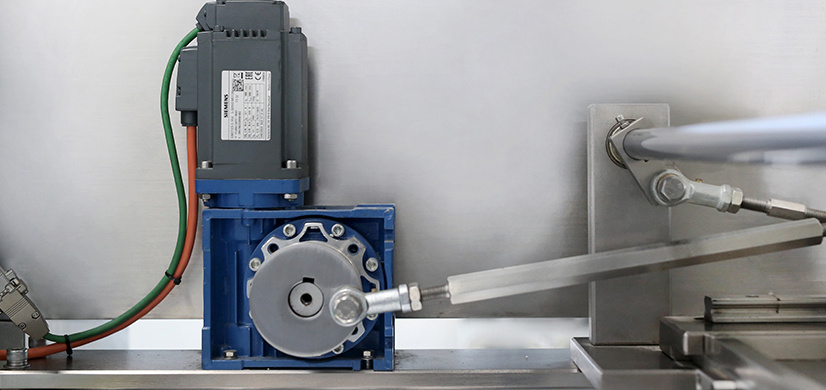

Sealing and Printing Mechanism

Sealing die diameter up to 100mm, high sealing pressure, transverse sealing using double sealing, die heating temperature using high-precision temperature control instrument, heating tube using multi-stage heating, so that the sealing set temperature and the displayed temperature error is controlled within 3°C, clear texture, good sealing performance.

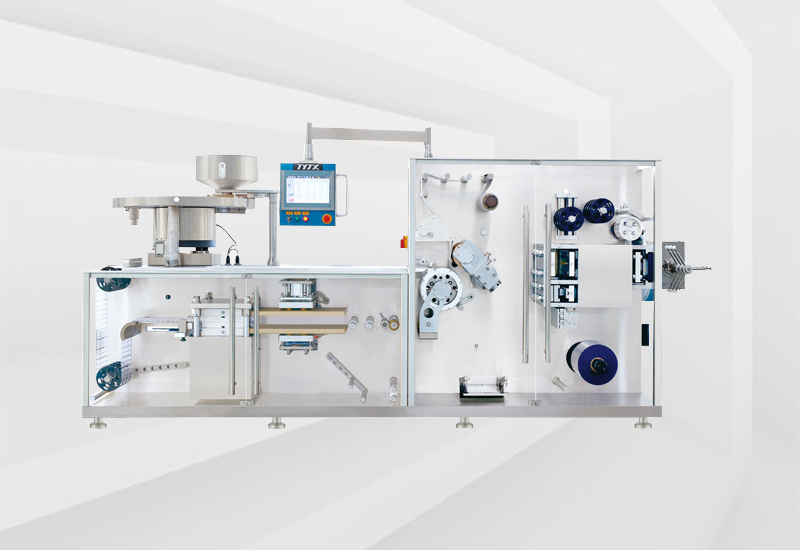

DXDK-1200 GRANULE PACKAGING MACHINE

Retail price:

Market price:

编号:

重量:

Quantity

-

+

Remaining inventory

隐藏域元素占位

- Product Description

-

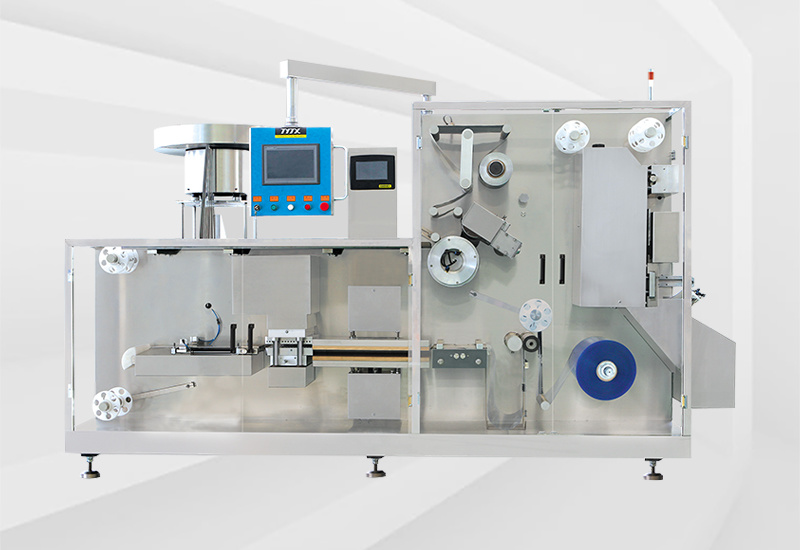

- Commodity name: DXDK-1200 GRANULE PACKAGING MACHINE

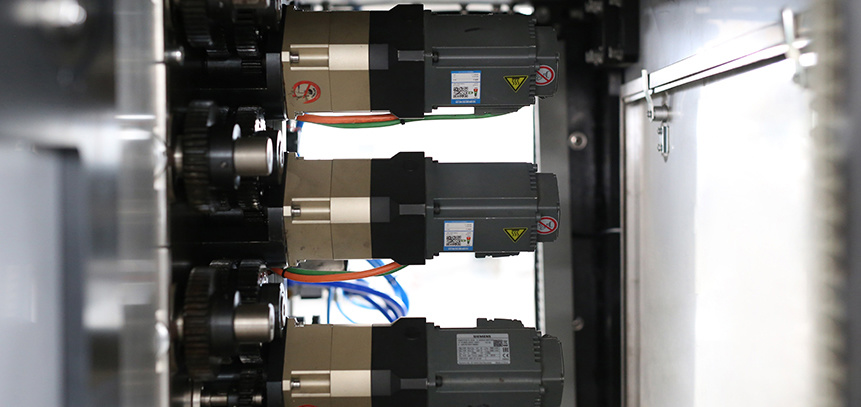

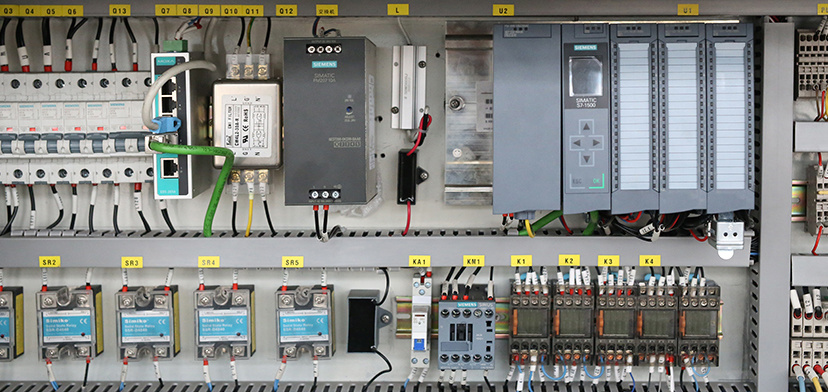

With advanced performance, high strength, low noise, compact structure, stable operation and long service life. This machine is suitable for packing loose and unbonded granule and powder materials, liquid materials,water-bindered pill , and small and medium-sized bags with measurement packing requirements. It is suitable with a variety of packaging film, such as PET/ALPE, PET/PE NY/AL/PE, NY/PE and so on.

Model DXDK-1200 Packaging Material(mm) ALU-PVC, Paper-Poly, Plastic and ect can be heating sealing material Packaging(mm) Width: Max 1200

Thickness:0.05-0.1

Outer Diameter: MaxΦ300

Inner Diameter: Φ70-Φ76Sealing format Width (mm) Max: 600 Bag Size(mm) Length: 60-180

Width: 50-150Filling capacity(ml) Granules: 0.5-20

Powder: 0.5-10

Packaging capacity(time /min) 50 Capacity(bags/min) Max 500(according to bag size) Power 380V 50HZ 18KW Size L×W×H(mm) 2010×1800×2100 Net weight(kg) 3000 Re:No additional information noted if there are any changed caused by the technical development.

More products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!